If you look down towards the feed mill at the end of my street you’ll see all of the haze we’re dealing with at the moment. That’s smoke from the Canadian wildfires and it’s so bad at the moment that they’ve issued warnings that its unhealthy to even be outside. When I go outside it frankly stinks like a trash fire. Someone on television said that being outdoors right for a day would be the equivalent of smoking a whole pack of cigarettes. Judging from the way it looks, smells and feels out there, I would think that is not an exaggeration.

There’s not much we can do about it. We have the house closed up tight, with three room sized HEPA filters running full out and the furnace fans circulating the air in the house through its filters. I’d love to be outside at the moment. Temperature is around 72 degrees, ideal for things like gardening, riding the bike, etc. But I had a severe case of bronchitis and/or pneumonia (they never did figure out which it was, exactly) some time ago and ever since my lungs were never the same so when things get like this I stay in the house as much as I can.

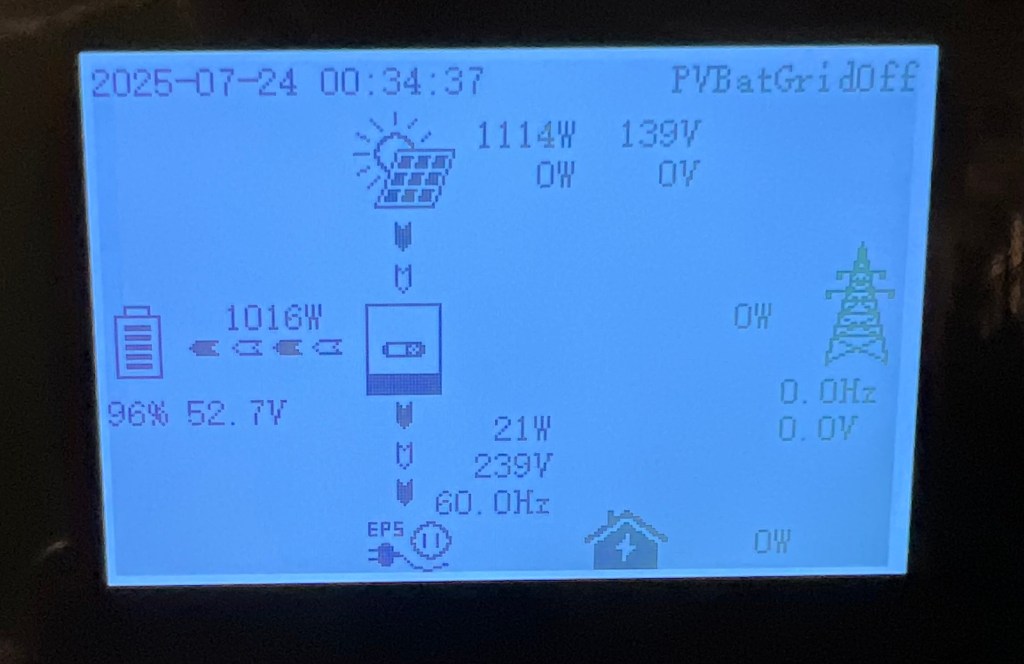

The EG4 12000XP is working nicely. Mostly. After getting the battery communications situation straightened out I have had a couple of curious issues with it that we’re working to resolve. More about that in a moment. Otherwise it’s been doing exactly what it’s supposed to do. In the photo above it’s hooked to a 2KW solar array. You’ll note that it’s only bringing in a little over 1 KW and that’s because of guess what? Yeah, the smoke. It’s amazing how the haze from the wildfire smoke causes solar production to plummet. Almost all of that power is going into the batteries in the photo up there because the house isn’t switched over to the inverter yet. The 21 W it’s currently showing is what the inverter itself uses.

I really like the display on this unit. It is so much easier to read and understand than the displays on the 6500EX units were. The 12000 shows pretty much everything I need to see right here on the main screen. With the 6500EX I had to scroll through a half dozen different screens to get the same information.

But the issues… Twice now I’ve had the inverter trip out with an “Overload” error message and my son and I are both scratching our heads over that because there was no overload of anything. At the time it tripped out the total load on it from the house was only around 2.5 KW total on both legs and this thing is supposed to be able to handle up to a 12KW load, 6KW on each leg. So what caused it to trip out?

I haven’t been able to do much experimenting with it because we’ve had so much cloudy weather of late. Hopefully I’ll be able to “exercise” it, so to speak, more fully once the weather clears up and we can track down what the problem is.

As you can see we’ve been harvesting onions and picking some of the young carrots. The onions are brought into the garage where they will be laid out on a screen for about two weeks to cure them. The curing process basically allows the outer layers of the onion to dry and harden which protects them from rot and mildew. They’re left to dry in a fairly warm, dry place for a couple of weeks to cure, then we pack them loosely into net bags and hang them from the ceiling in the basement for long term storage. If properly cured and then stored they can last for months.

We also just peel them, dice them up and freeze them for use later in sauces, chili, tacos, etc. The texture does break down and they get soft but the flavor is still there. We do the same thing with cilantro, freezing it in blocks in ice cube trays in either water or olive oil. That works out really well. When we’re making chili or tacos or something we just pull out a cube of cilantro and throw it in the pot with the rest of the ingredients.

My wife and I both love cone flowers. They’re in all their glory right now. They put on a double show for us. First when the come into flower like they are right now, and then in the fall after the flowers have faded and the finches go after the seeds. We’ll get dozens of goldfinches coming to feast on the seeds in the fall. And best of all, it takes us zero work and expense to grow them. enough seed falls to the ground that they re-seed themselves and they don’t require any work at all in the gardens. They’re even quite drought tolerant.

Someone asked if I was still going out on the bike and the answer is definitely yes. I just don’t bring it up much here because I figured people were getting bored with it. I try to put on 10 – 15 miles a day, three or four days a week, and about 5 miles the other three or four days.

I have one of those Garmin fitness tracker thingies with built in GPS. I tried one of those fitness tracker aps on my phone but most of them are worthless and the ones that actually worked reasonably well deluged me with non-stop spam trying to sell me subscriptions and I don’t know what all else. All I want is something that records milage, shows my route, and that’s about it.

It’s a Garmin Edge 130. It’s a tiny little thing that clips to the handlebars of the bike. It has a fairly small, black and white LCD screen that displays things like elapsed time, speed, etc. It’s handy little gadget if ridiculously pricy. I think the dopey thing goes for about $200 these days. That’s like twice what I paid for mine a couple of years ago. I’m not sure why the price has damn near doubled since then.

I am not recommending you get one. I honestly don’t think it’s worth $200. It pairs with an app on my iPhone that gives me all sorts of data that I really don’t give a fig about, to be honest. I don’t know why people obsess so much about things like calories burned, cadence, respiratory rates, hydration and all that guff. If I were in training for the tour de France yeah, I might care. But I’m just an old duffer who likes to know how far he’s gone and can show the wife a map of where I went so she doesn’t think I’m cheating and only getting as far as the local pub.

When I’m out in the country on the bike I might bop along at 10 – 14 MPH but it’ll take me two hours to do 10 miles because I’m constantly stopping to take photos. Every time I come across a cluster of flowers or some interesting looking plants or hear an unfamiliar bird call I’m stopping and looking and listening and photographing. When you run into clusters of flowers like those up there in that photo how can you not stop and look?

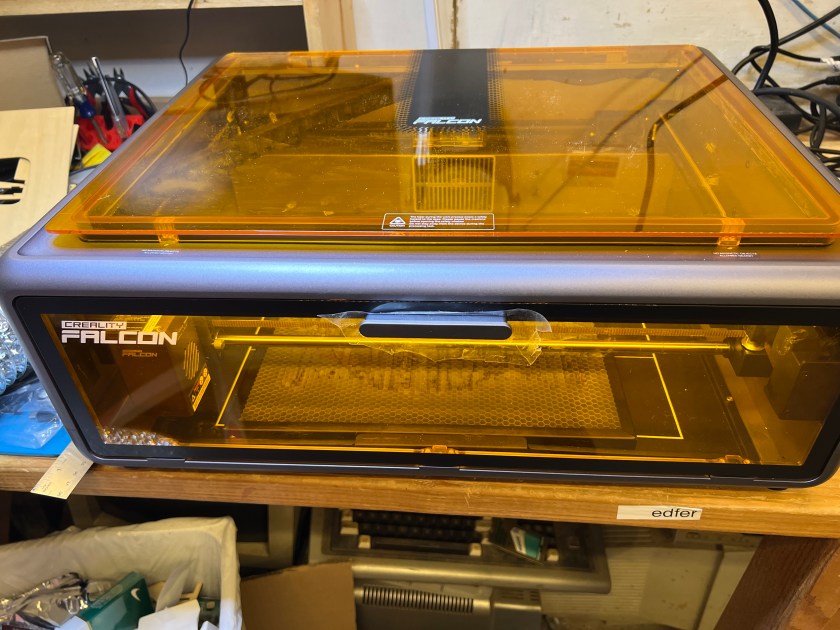

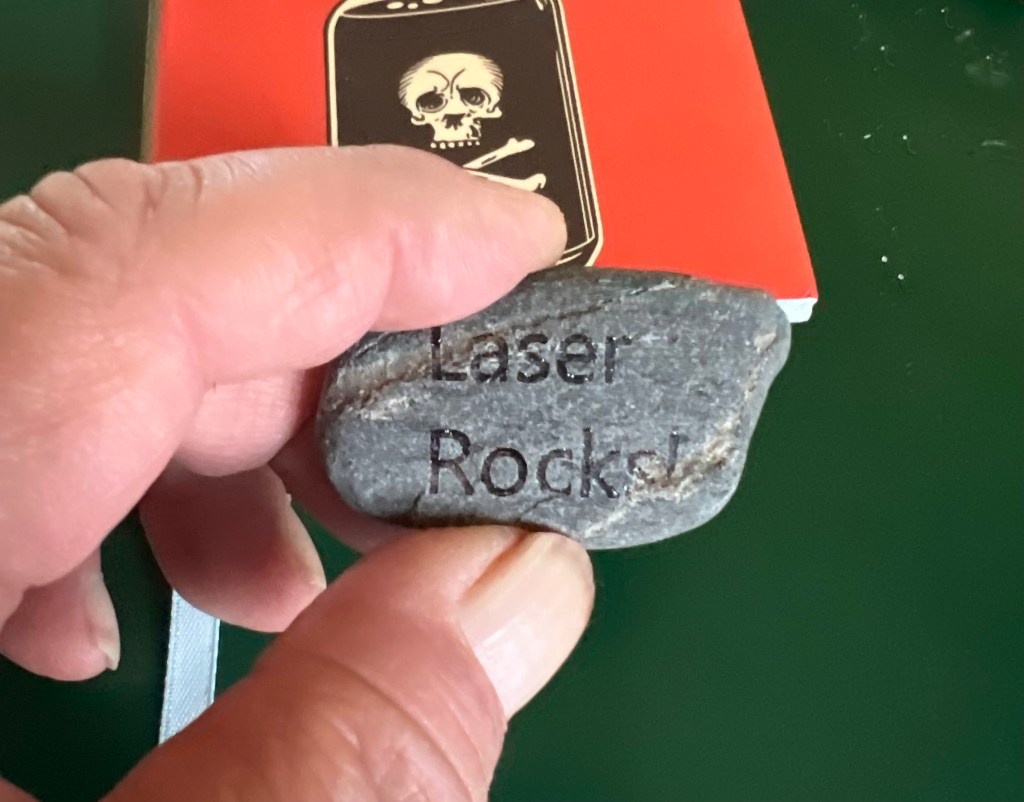

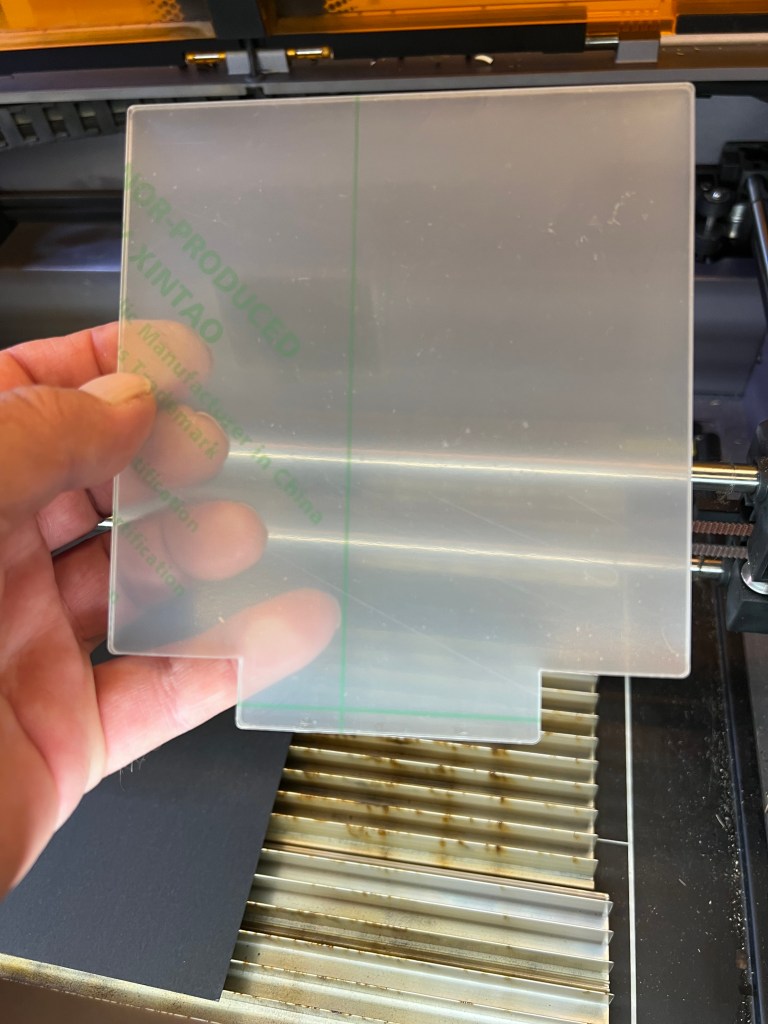

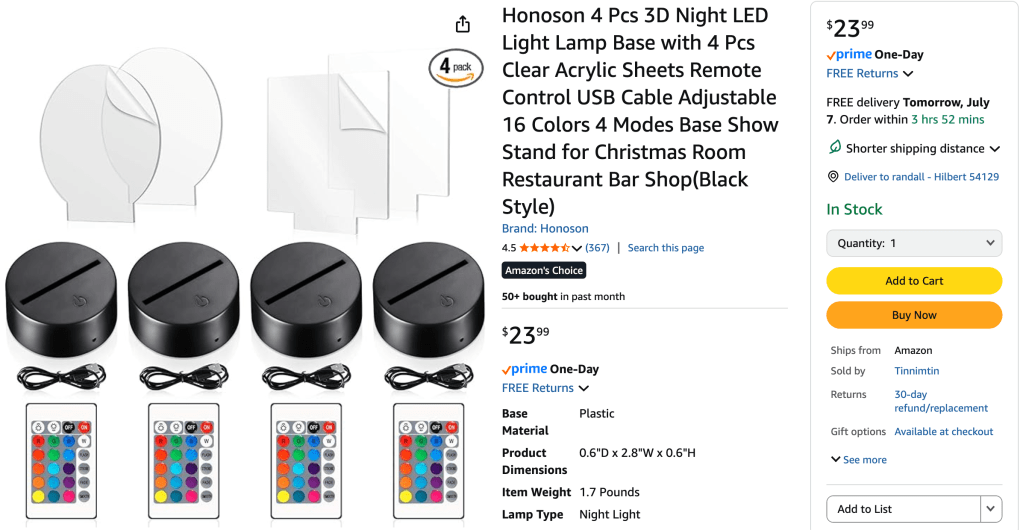

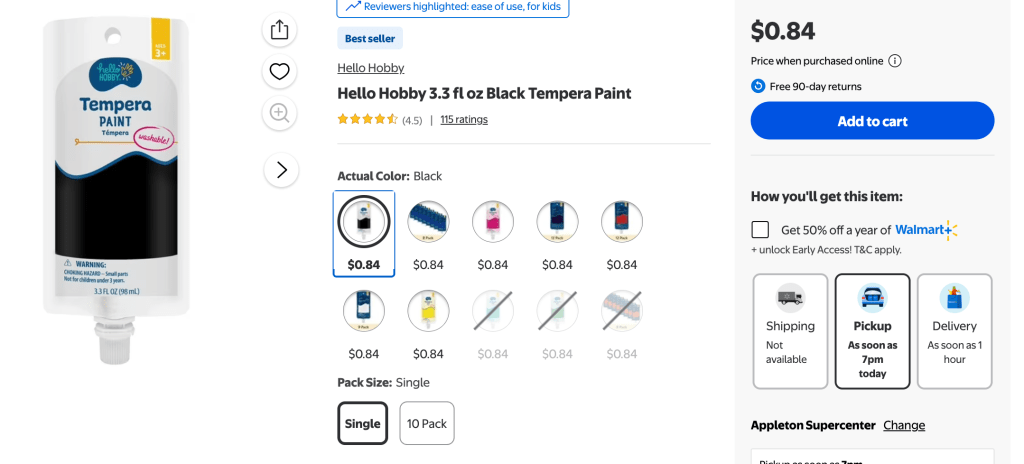

And I’m still experimenting with the Falcon laser. I’ve been fiddling around experimenting with doing inlay and other things. I was wondering if I could get a sort of stained glass effect by inlaying translucent acrylic into wooden outlines and that seems to actually work in the simple experiments I’ve tried. I’m also going to try combining it with another hobby of mine, making epoxy resin castings to make decorative panels. If anything comes of that I’ll let you know.