… here over the last few weeks. I’m not sure what the heck happened after I retired. I was supposed to have all this free time to play with amateur radio, do gardening, dabble more in photography, go fishing, etc. Instead it seems I have less time than when I was working full time. Oh, well.

We did go up north last weekend to visit some friends, although we did run across this —

We came across the rolled over milk tanker about 10 miles from the house. Fortunately no one got seriously hurt. I think he was empty because there was no leakage when we came across the scene just after it happened. It was on a roundabout, and this happens on a regular basis with these big trucks. They hit the roundabout too fast and flip over trying to make the corner.

The annual Chilton steam engine and antique tractor show was this weekend and that’s something I try to get to every year even though it makes me feel so old sometimes to see equipment that I used to run when I was a kid or teenager now classified as “antique”. Although to be fair a lot of the equipment we had on the farm back then was probably already antique by the time we got our hands on it.

This year the big surprise was this —

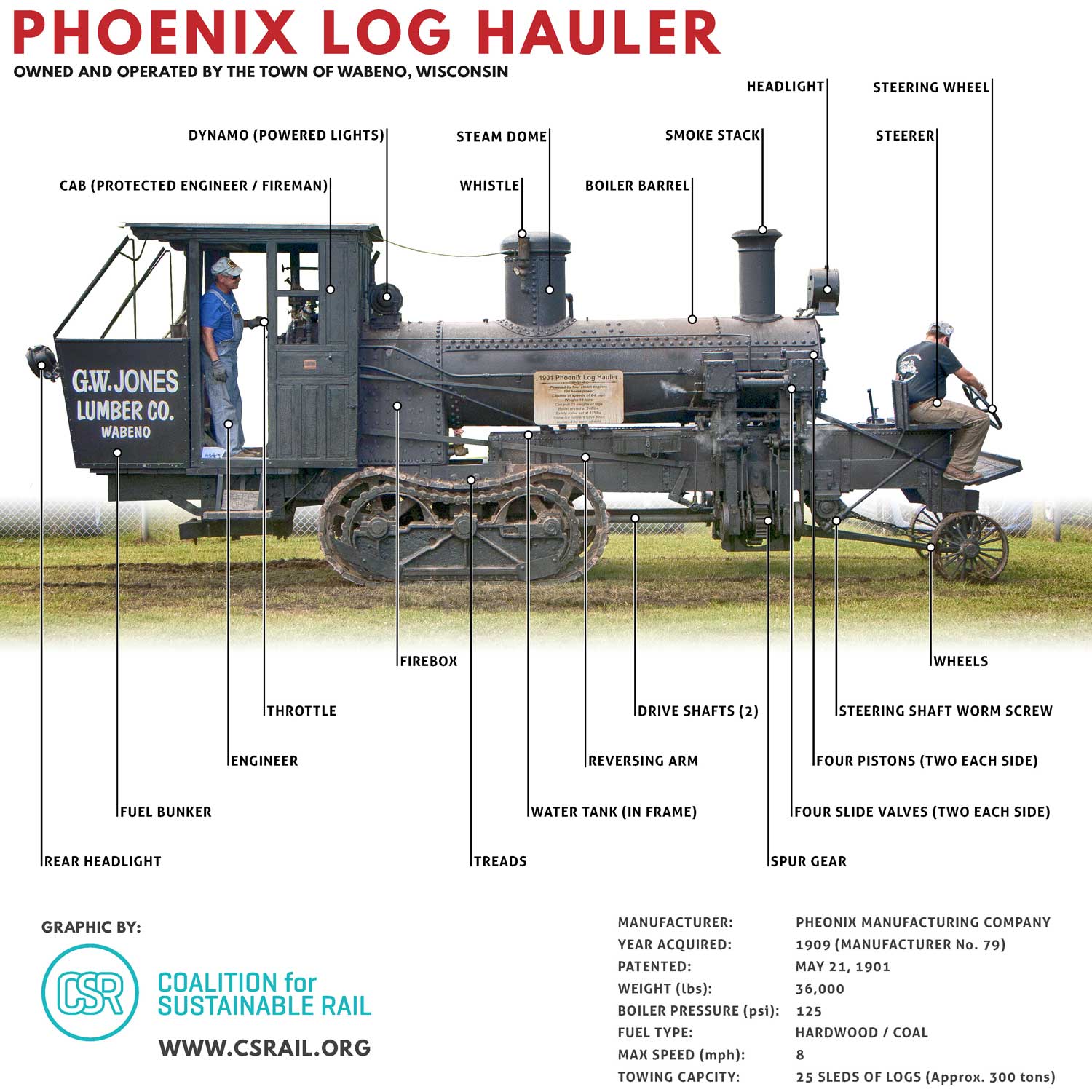

Now if you’ve never seen anything like that before, it’s for a good reason. They never made many of these, and there are only three of them left in the world from what I learned talking to the guy who was operating it. When I first saw it, it was largely blocked from sight and all I could see was part of the front with the engines and I thought someone had lugged a Shay type locomotive to the show.

Yes, it’s fully operational. This isn’t just a static display, it actually runs.

What the hell is it? It’s a log hauler that was used up until the 1930s to pull huge sleds carrying logs through the woods during the winter. Only about 175 of them were ever built. It could pull up to 300 tons of logs on as many as 25 sleds at a time. I ran across this when I was looking up more info on it-

I can’t even begin to imagine what it must cost to keep that engine repaired and operational. It must be incredibly expensive. I’m very glad they do, though. If it weren’t for people who support the preservation of equipment like this all we’d have are photos. They show it at Wabeno, where its home is, but they also take it out to at least one of these shows a year.

As I said, sometimes it makes me feel very old when I go to these and run across equipment I used to use, like this Massey 44. I used one of these when I was a kid. For a long time it was our primary tractor that did everything from hauling out manure to chopping feed to plowing. And while it may look pretty and make me feel nostalgic, when it comes down to it it was a nasty, nasty tractor to actually use. The front end was too light. Those front wheels would be entirely off the ground as often as not when it was pulling a heavy load. It was difficult to steer. It had mechanical issues. The engine was decent, but ours tended to overheat and the transmission wasn’t very good. And it sucked gas like you wouldn’t believe.

What I like about these shows too is that it gives us a glimpse into what life was like for our not so distant ancestors. Just the simple job of washing clothing was a major operation not that long ago.

Yes, that’s a washing machine being powered by an ancient gasoline engine. And while that engine might be a bit elderly for this setup, washing machines running off gasoline engines was not uncommon in rural areas. You have to remember that a lot of rural areas didn’t get electric service until the 1930s or even later.

On the amateur radio front, I’ve been fiddling with antennas again. Well, sort of. I’m finally getting around to getting the Gap Titan vertical finished and hooked up.

It successfully survived the winds we had during the recent storms. After 60 – 70 MPH winds hit us during those storms I more than half expected to see it laying on the ground when I got up the next morning, but it made it through unscathed. We almost forgot to put guy lines on the thing. If we’d neglected that I’m sure it would have come down.

I got the counterpoise/ground plane installed finally and, well, it takes up a wee bit bigger area than I thought it would. Going to be fun mowing lawn through there. But that area is going to be part of an extension to the existing flower beds anyway so I only have to worry about it for the rest of this season.

And I still don’t have the dopey thing connected. I got started, got all the tools out and began to work on putting the connectors on the coax and… Sigh…

I had the wrong one. I needed a female and only had the male variety, so I either needed a female or an adaptor. Not a big deal, but mildly annoying nevertheless. In any case, I didn’t really like the style connector they sent with the antenna in the first place. Thankfully, Farm and Home, the big hardware store down in Chilton has a big electronics section (used to be a Radio Shack store) and they’ll probably have what I need.

As for the weather – this has been one of the wettest summers I can remember. The lawns should all be brown and dormant from a lack of rain this time of year. Instead they’re all lush and green, as you can see from the photo there. I’ve only had to water the gardens about three or four times all summer long so far. Most summers watering is something we need to do every two days or so.

The rivers and lakes are all abnormally high around here because of all the rainfall.

This is the river down by the old stone bridge the other day. Normally this time of year the river is so low and stagnant that it’s choked with algae and weeds, and so shallow it would hardly be halfway up your shins if you tried to walk through it. It’s a good four feet deep or more, though, and had more than enough current to keep the algae from accumulating.

That’s about it for now. Hopefully by the next time I get around to writing something I’ll have some amateur radio stuff to talk about. I should have that antenna finally set up. I should have the new Yaesu 818ND up and running with the laptop using FT8, JS8Call and PSK.

And hopefully I’ll have made some progress in moving all my equipment down into the basement. MrsGF found a matching set of old, heavy duty tables at St. Vinnie’s that might make good work benches. They’re about 4′ square with heavy duty 4″ square legs. They’re beat up but look solid, and I can get ’em for $5 each, so I’ll go take a look at those on Tuesday.

Still have to make a decision on where the electrical outlets are going to be placed down there, but I didn’t want to do that until I had an idea on where the work benches were going to be, how tall they were, etc. Probably at least 4, four outlet boxes fed with 20 amp circuits, plus at least one 240V outlet for amplifiers. And need to rewire for better lighting. Want to put in LED lights to replace the existing fluorescent tubes that are in there now.