Covid update: I am more or less now symptom free. Almost. I am still testing positive however so there’s that. But I guess it’s normal to keep testing positive for a week or more even after symptoms have cleared up because virus fragments remain in the body that the test is picking up. I am probably no longer contagious but I’m still reluctant to go anywhere where I might come in contact with people while I’m still testing positive just in case.

Laser stuff

I’m having way too much fun with this laser stuff. I got bored the other day and found a project on the Crealty Falcon project collection that looked interesting so I loaded that up, ended up with a whole box full of misc. parts, sort of like a big 3D jigsaw puzzle, dug out a set of acrylic paints and glue and the next thing I knew I had this sitting on the table.

Considering this is the first time I’ve tried something like this I think it turned out rather well and I’m pleased with it. It’s simple and sort of abstract but I think it’s reasonably attractive for a first effort. My painting skills leave a great deal to be desired but then this is the first time I’ve done something like this.

It also reminded me how much I used to enjoy building models. Many, many years ago I had a model railroad layout in the basement. It had to be dismantled to make room for the woodshop when we started remodeling the house and I was never able to put it back up. But it reminded me of how much I enjoyed building models for the railroad. I had so much fun doing this that I’m going to be scouting for other projects like this and maybe even design some of my own.

But back to the laser thing. I’ve been enjoying using it so much that I’m seriously considering doing a significant upgrade in equipment here to replace the Falcon. Don’t get me wrong. I love the Falcon. It’s a great piece of equipment at an excellent price. But when it comes down to it, it is still just a 10W laser with some serious restrictions.

I’ve been looking at the 45W Vision Pro from WeCreat. the same company that makes my Lumos. My experience with the Lumos has been so positive that I’ve become interested in their other equipment. The Vision Pro can handle much, much thicker material. Instead of being limited to thin plywood it’s powerful enough to cut actual real boards among other things. It has autofocus and other goodies built into it that make it very attractive indeed.

What’s holding me back is the cost. Am I going to get enough use out of it to justify the cost? As MrsGF has pointed out I don’t do this as a business except for the promotional materials I crank out for the brewery and I am too lazy and unambitious to try to turn this into a business. So is it worth the money to upgrade the laser just for goofing around?

But on the other hand, when compared to what some people I know spend on their hobbies, what I’m thinking of spending isn’t all that bad. I know fellows who’ll drop more on a single engine for their model railroad than what I’d like to spend to upgrade my laser.

Materials

Speaking of costs, I want to talk about materials for a minute. Don’t make the same mistake I just did and make a bulk order of material without getting samples first. I needed some 5mm plywood and bought some of this stuff over there on the left and it is horrible. It looks fine in the photos but in reality it is not nice at all. The surface is rough and sandpapery. While it appears to not have a prominent grain in the images, in reality when engraved the grain becomes very visible and is so coarse it’s just downright nasty. Even worse is the charring. I’ve never run into a plywood that chars and smokes this badly when engraving. Huge billowing clouds of smoke that almost overwhelmed my extraction system and massive amounts of charring that left black dust everywhere. The stuff is completely unusable with the laser. And now I have 50 sheets of the stuff and it’s probably going to end up being used as firewood.

Anyway, be cautious when buying materials. You might be tempted to snag a great deal on a bulk purchase and end up with stuff that’s completely unusable as I did.

New Toy

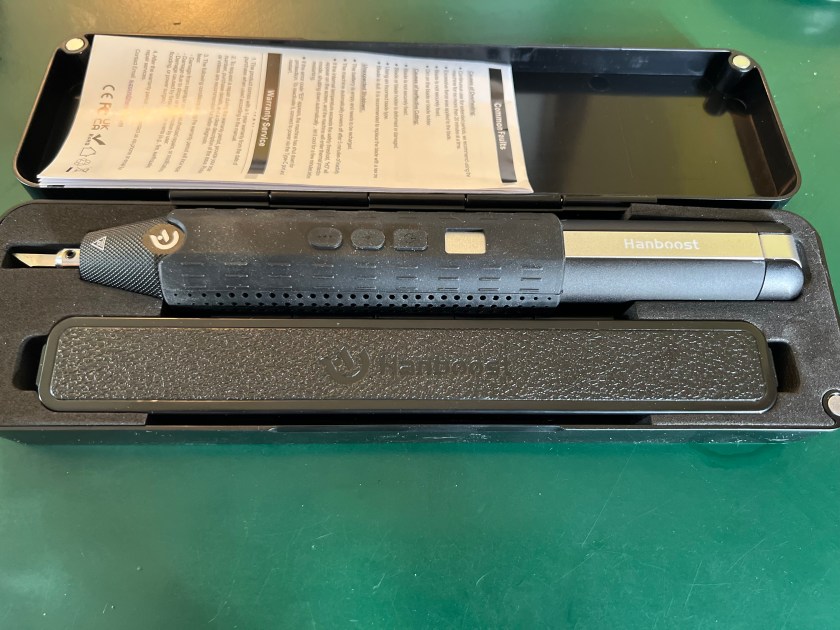

This is an ultrasonic knife from a company called Hanboost and I’m trying to decide if it’s something I’d recommend or not.

The way these things work is interesting. It takes a razor sharp titanium blade and vibrates it many thousands of times per second. The idea is that the extremely high vibration rate of the blade causes it to glide through material with virtually no effort at all on the part of the wielder. In theory. It seems these things are popular in the 3D printing world where they are used to clean up plastic prints. And someone told me that they work equally well for trimming wooden parts that are laser cut and don’t quite fit properly.

Some of the parts for that house I showed you earlier didn’t fit together properly and I used this thing to trim things to get them to fit and it did work, but results were inconsistent. There were times when it sliced through the plywood like a hot knife through butter. Other times it worked awkwardly and didn’t seem to work much better than a normal Xacto knife. I suspect that at least part of the problem there is my technique. There is a learning curve to developing the right technique to take advantage of this thing.

Overall I like it despite the problems I had. It seems extremely well made and has a nice feel to it and is easy to control. But there is the cost to consider as well. This thing ain’t cheap. It goes for about $190 on Amazon. You’re going to need to use it a lot to justify that kind of expense.

And that’s about it for this time.

Glad you’re feeling better! The rest of the post? Greek to me. ☺️

LikeLike

thanks Nan. Yes, some of this stuff gets a bit technical and unless you’re into lasers and all of this stuff it isn’t going to be very helpful.

LikeLike

I rejoice in your covid recovery and I thank The Lord for answers to prayer. Be healthy; be happy; be blessed.

LikeLike

Thanks John.

LikeLike

GReat news that you are better and it looks like you have had time to piddle around with your toys….sounds like MrsGF is keeping you on the straight…..chuq

LikeLike

Doing much, much better. Still testing positive for Covid but I’m told that’s common and could last for another week? Sheesh…

I do love my toys Which is why MrsGF is generally in charge of the finances around here.

LikeLiked by 1 person

Sounds like a wise move. chuq

LikeLike

Covid is something to celebrate getting over. I say, buy that new toy, you know, to celebrate!

LikeLike

I just about have myself talked into it just because of the increased cutting capabilities. The one I have now can cut 8mm (about 1/4″) plywood. Barely. It has to go very, very slowly and make 2 passes to get through it. The one I’m looking at can cut up to 3/4 inch softwood. 1/2″ hardwood, and has an optional feed roller system that would let me work with boards up to 15″ wide and up to 5+ feet long. I could work with actual real wood in sizes large enough to make real furniture. Total cost would be under $3,000 including the feed roller system. I am very, very tempted. I can’t get a decent tablesaw for that kind of price these days.

LikeLike

Man, that sounds like an impressive machine! At this point in my life I figure it like this, I want to enjoy the years I have left. If I can reasonably afford to allow myself a few things that make me happy, fuck it. Let’s do it! I don’t want to take on a lot of debt, to accomplish that, but I could stand a little if I needed to.

LikeLike

All things considered it isn’t a huge amount of money, about $2,500. A good table saw or lathe would set me back more than that these days. The ability to cut 1/2 – 3/4 inch thick lumber would open up all kinds of fun possibilities. Anyway, we’ll see what things look like after the accountant gets done with our taxes. Probably wouldn’t do anything until then.

LikeLike